AMPCO PUMPS COMPANY

Ampco Pumps Company offers the most complete line of centrifugal pumps, positive displacement pumps, dry blenders and powder mixers in the world.

DESIGN AND INNOVATION

- The patented ZP3 and ZP1+ are designed to offer easy maintenance and reduce processing down time.

- ManyofAmpco’spumpsandpartsare100%dimensionally hydraulically and part-for-part interchangeable with competing brands.

DEDICATION TO CUSTOMERS

- Ampco offers premium upgrades, including a free stainless steel gear case on each new positive displacement pump.

- Dedicated sales team and customer service staff

- The best delivery times in the industry

- Custom specifications are welcome

- AmpcoPumps.com provides technical information for distributor and customer success including a pump sizing program, product cross reference guide, manuals and literature.

- Ampco pumps are shipped globally through a growing distributor network.

- Manufactured, assembled, and tested in Glendale, WI since 1948

ZP PUMPS SERIES

ZP1+ SERIES

Patent Pending ZP1+ Easy Maintenance and Reduced Downtime

Ampco continues to bring innovation to the sanitary pump market. We have enhanced the traditional design of the popular ZP1 pump and are pleased to introduce the NEW ZP1+ (available in models 30 and larger) for ease of maintenance and reduced downtime.

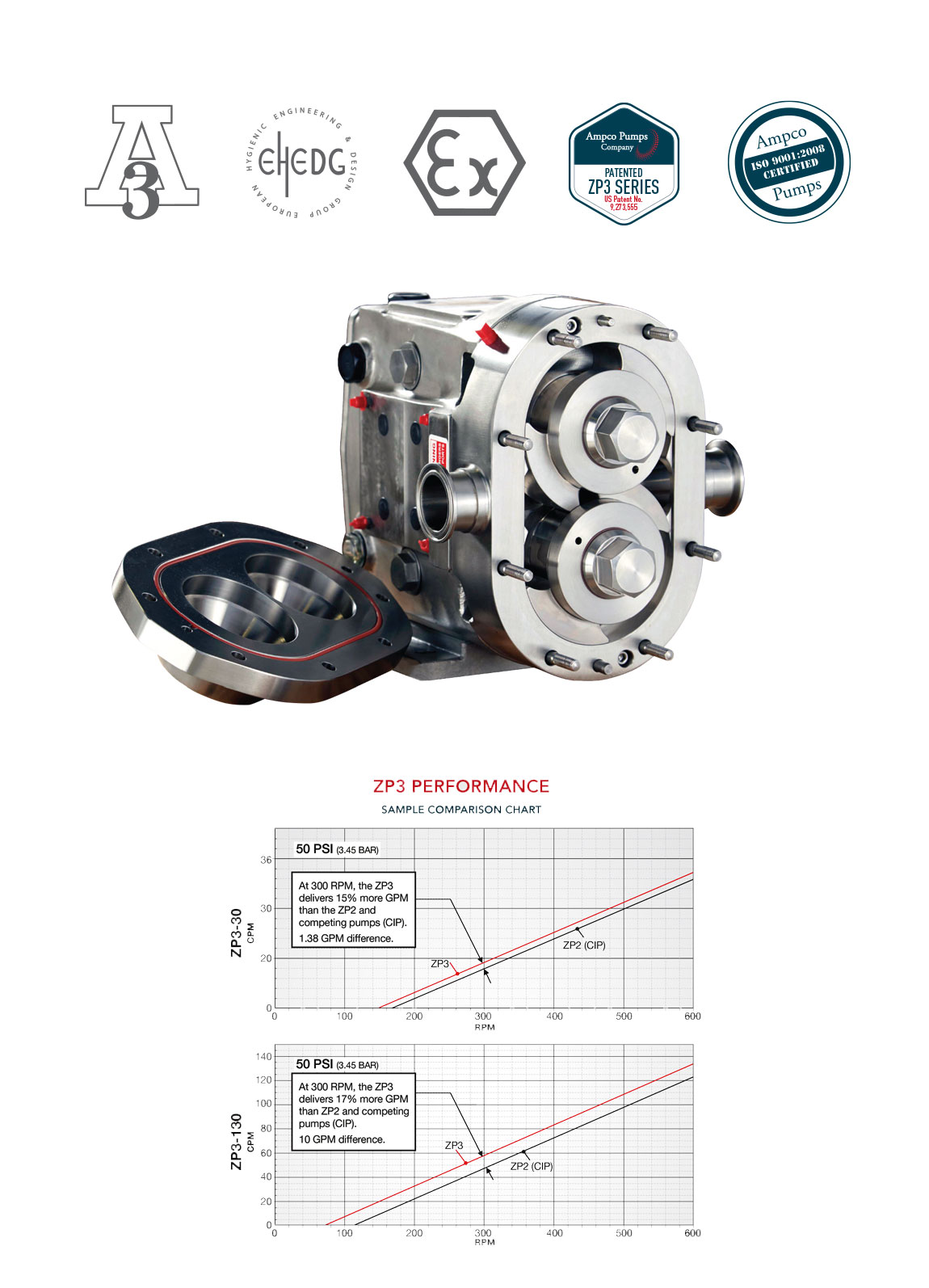

ZP3 SERIES

THE SIMPLE CHOICE FOR SANITARY PROCESSING

Ampco’s patented ZP3 Series is CIP-able without modification or loss of efficiency. The front-loading seal design reduces maintenance time and costs.

ZP3 SERIES FEATURES

- Front-loading seals are located closer to the product flow, offering improved CIP-ability with no disassembly required.

- Front-loading seals allow for ease-of-maintenance and reduced service time. Maintenance personnel no longer need to disconnect the pump from piping.

- EHEDG Certified and in conformance with 3A Sanitary Standards and the ATEX Directive.

- Cover design maximizes exposure of the cover o-ring to the CIP fluid.

- Free drain design improves CIP-ability while maintaining maximum pump efficiency.

- CIP holes in rotor ensure turbulent flow to the cover hub.

- Elimination of dead zones in shaft bore improves cleanability and increases seal life.

- The ZP3 pump is mounted on a ZP2 gear case, including shafts, to maximize parts interchangeability.

- Existing ZP2 pumps (and our competitors’ similar pumps) can be upgraded to the ZP3 design with new rotors, seals and re-machining the existing rotor case.

- New pumps can be reconditioned 2 to 3 times.

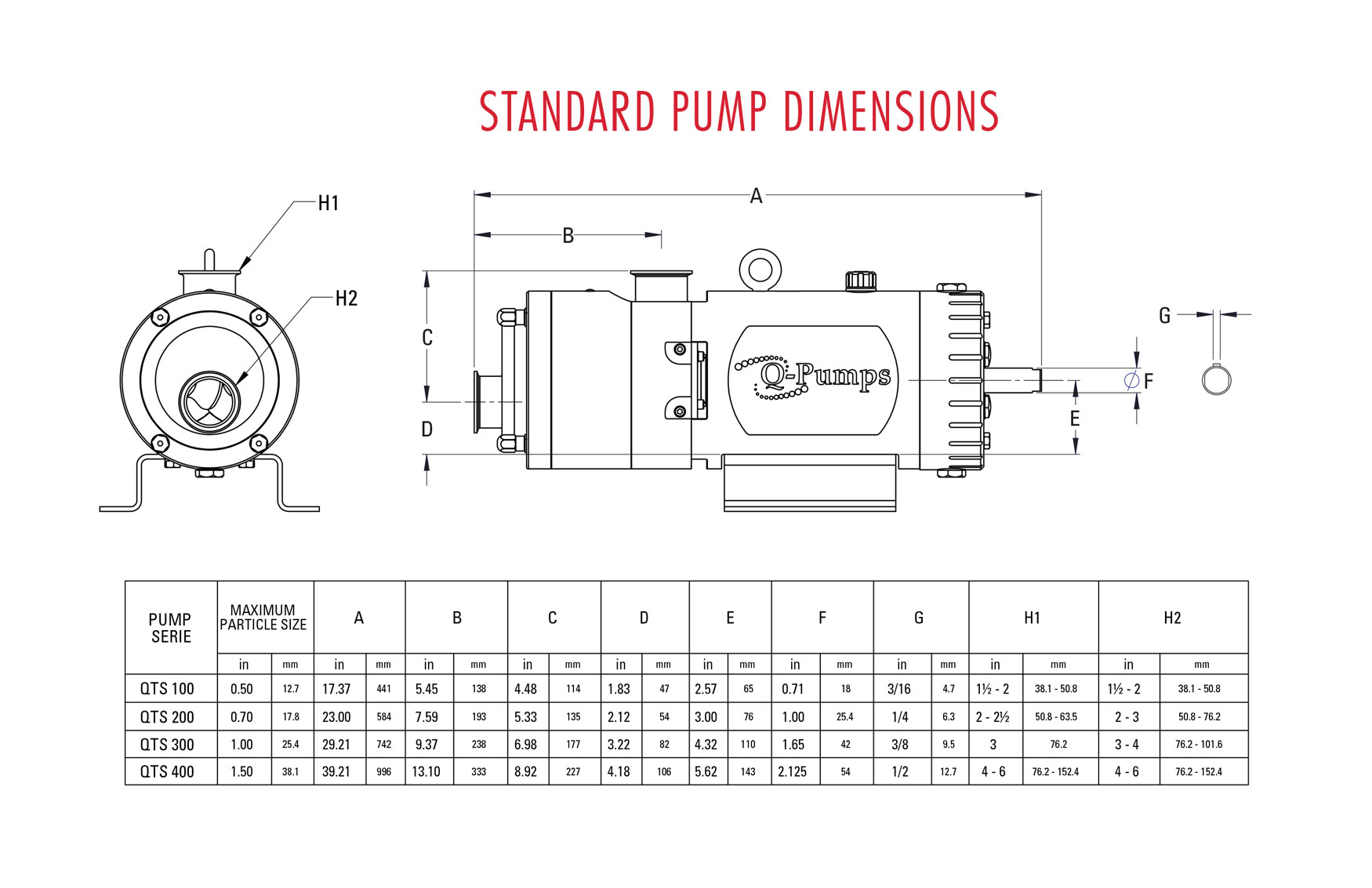

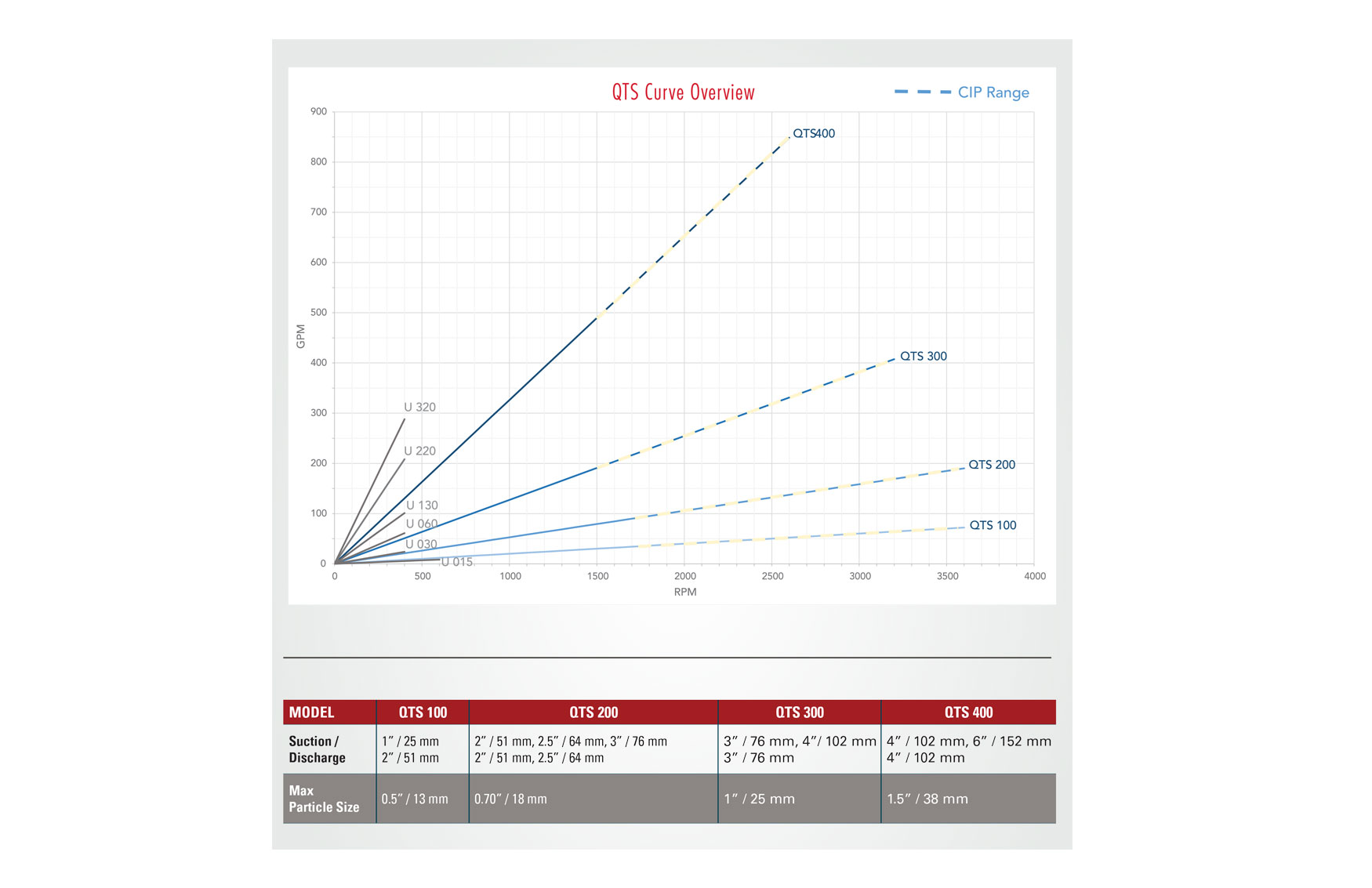

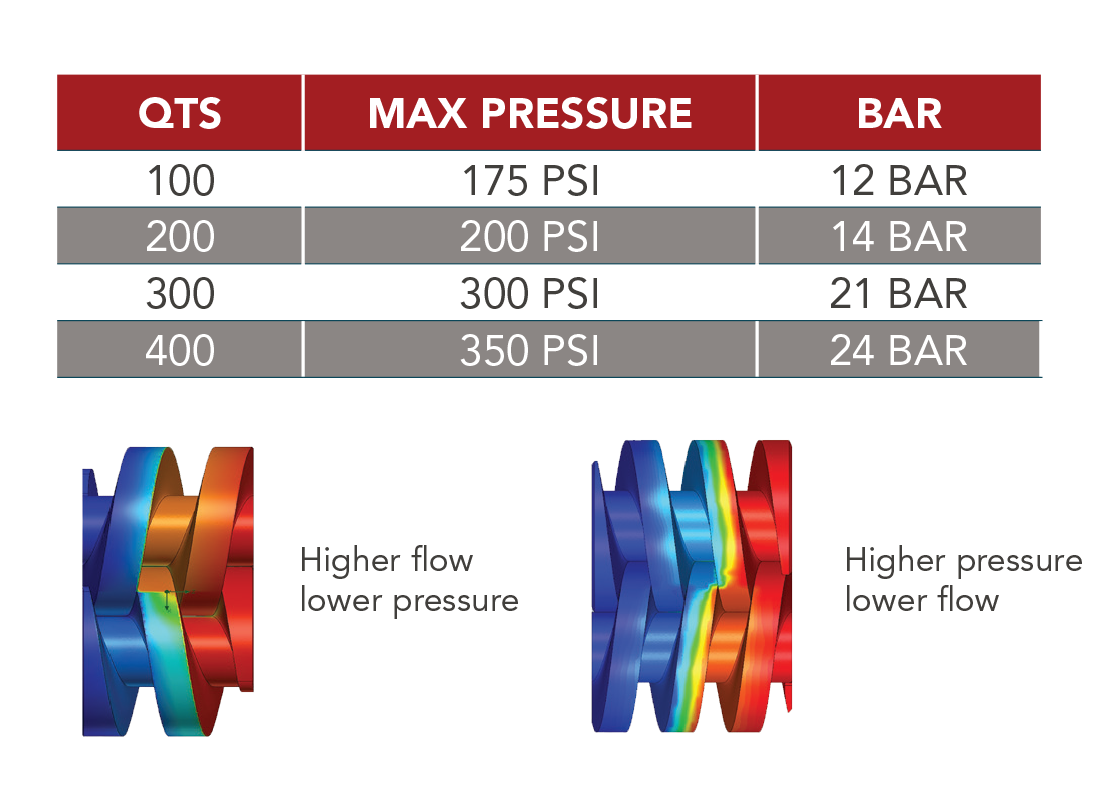

QTS TWIN SCREW PUMP

The latest addition to the extensive and innovative positive displacement pump offering from Ampco Pumps Company. The QTS was engineered for gentle handling of viscous products and media with larger soft particulates.The QTS is manufactured with a robust design to provide durability, quiet operation and virtually pulsation-free pumping.The QTS standard offering includes added features that make this pump the best value in the industry today. Replacement parts are in stock and attractively priced.

The QTS is a dual duty pump that can be applied for both process and CIP requirements.

ROTORS

• Standard and hot clearance rotors are available

• Three pitch options per model

PRESSURE RATINGS BY MODEL

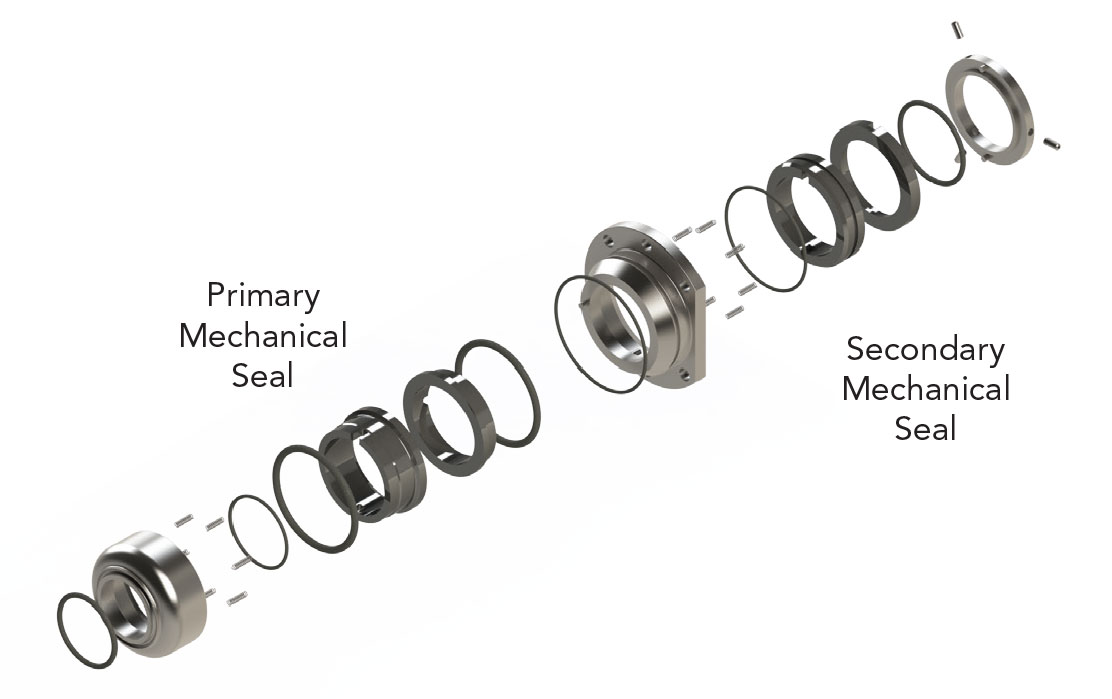

QTS MECHANICAL SEAL

- Single mechanical / Double mechanical / Lip seal

- Easily converted from a single seal to a double seal, all models come double seal ready

- Seals are capable of handling a vacuum of 28” of Hg

- Seal and service kits are at the factory ready for immediate shipment

- Lower cost than the competition